chain guides

Chain Guides: A Comprehensive Overview (Updated 02/15/2026)

Today, February 15, 2026, chain guides are crucial for preventing derailment, reducing noise, and extending chain life across diverse applications like bicycles and industrial drives.

What are Chain Guides?

Chain guides are essential components designed to maintain proper chain alignment and tension within a drive system; They effectively prevent the chain from falling off the sprockets or gears, a common issue, especially in demanding applications like 1x bicycle drivetrains. Constructed from materials like nylon plus fiber or Saigang engineering plastic, these guides ensure smooth, reliable power transmission.

Their primary function is to mitigate chain derailment and jumping, contributing to increased efficiency and reduced wear on the entire system. Proper installation and utilizing manufacturer-prescribed replacement parts are vital for optimal performance and preventing potential damage.

The Importance of Chain Retention

Maintaining chain retention is paramount for uninterrupted power transfer and operational safety. A dropped chain can halt operations, cause damage to components, and even pose a safety hazard. Chain guides actively prevent these issues, ensuring consistent performance whether on a bicycle trail, motorcycle, or within complex industrial machinery.

Effective retention minimizes downtime, reduces maintenance needs, and extends the lifespan of both the chain and associated drivetrain elements, ultimately improving overall system reliability and efficiency.

Types of Chain Guides

Chain guides vary based on application and design needs. Inner chain guides sit closer to the chainring or sprocket, providing primary retention. Outer chain guides offer a secondary layer of security, preventing derailment outwards. Roller chain guides utilize rollers to minimize friction and wear, enhancing smooth operation and longevity.

These guides are constructed from materials like nylon plus fiber or Saigang engineering plastic, each offering unique benefits regarding durability and performance characteristics.

Inner Chain Guides

Inner chain guides are strategically positioned near the chainring or sprocket, acting as the first line of defense against chain derailment; They effectively prevent the chain from falling off during operation, particularly crucial in demanding conditions like off-road cycling or high-torque industrial applications.

Constructed from durable materials, they ensure reliable performance and contribute to a smoother, more efficient power transfer system.

Outer Chain Guides

Outer chain guides complement inner guides by providing additional security, typically mounted on the derailleur or frame. They prevent the chain from dropping outwards, especially during aggressive shifting or bumpy terrain, enhancing overall chain retention and system reliability.

These guides work in tandem with inner guides to create a robust barrier, minimizing the risk of chain loss and ensuring consistent performance across various riding or operational scenarios.

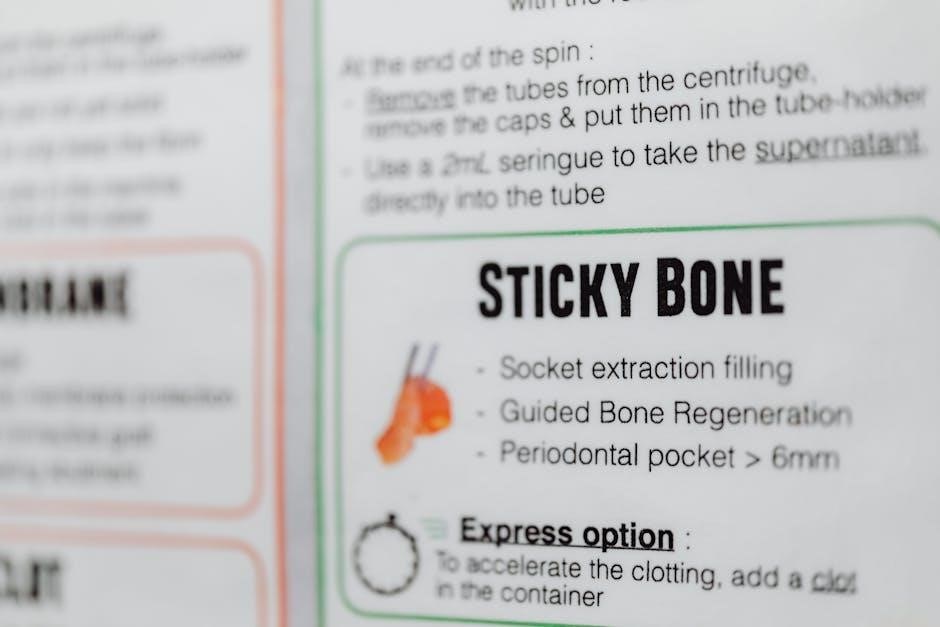

Roller Chain Guides

Roller chain guides are specifically designed for industrial chain drives, ensuring precise chain alignment and smooth operation within complex machinery. These guides manage the chain’s path, preventing excessive wear and maintaining consistent power transmission efficiency.

Constructed from durable materials like nylon plus fiber or Saigang engineering plastic, they contribute to extended component life and reduced downtime, vital for continuous industrial processes.

Materials Used in Chain Guide Construction

Chain guide construction relies heavily on materials offering durability and low friction. Nylon plus fiber guides provide excellent wear resistance and noise reduction, suitable for many applications.

Saigang engineering plastic guides offer superior strength and stability, particularly beneficial in high-stress industrial environments. Selecting the correct material is crucial; always adhere to manufacturer recommendations for replacement parts to avoid potential saw damage.

Nylon Plus Fiber Guides

Nylon plus fiber guides represent a popular choice due to their effective chain retention capabilities, actively preventing both chain drops and unwanted chain jumping during operation.

These guides excel in minimizing friction and reducing operational noise, contributing to a smoother, quieter experience. Their lightweight nature doesn’t compromise durability, making them ideal for applications where weight is a consideration, offering a balance of performance and practicality.

Saigang Engineering Plastic Guides

Saigang engineering plastic guides offer robust performance and longevity, designed to withstand demanding conditions within chain drive systems. These guides are engineered for high wear resistance, ensuring consistent chain control and minimizing the need for frequent replacements.

Their precise molding allows for tight tolerances, contributing to smooth operation and reduced vibration. Utilizing these guides helps maintain optimal chain alignment, extending the lifespan of both the chain and associated components.

Chain Guide Applications

Chain guides find diverse applications across numerous industries, notably in bicycles – particularly 1x drivetrains where dropped chains are a common concern. They are also essential components in motorcycle chain drives, ensuring secure power transmission and rider safety.

Furthermore, industrial chain drives heavily rely on chain guides for maintaining alignment and preventing disruptions in heavy-duty machinery. These guides contribute to operational efficiency and minimize downtime across various sectors.

Bicycle Chain Guides (1x Drivetrains)

For cyclists utilizing 1x drivetrains, chain guides are becoming increasingly vital; These systems, while simplifying shifting, are more prone to chain drops, especially on rough terrain. A well-designed guide effectively prevents derailment, allowing riders to maintain momentum and focus on the trail.

Thankfully, dropped chains are becoming “a thing of the past” with the implementation of these guides, enhancing the overall riding experience and reducing frustrating interruptions during adventures.

Motorcycle Chain Guides

Motorcycle chain guides play a critical role in maintaining drivetrain integrity and rider safety. These guides, constructed from materials like nylon plus fiber or Saigang engineering plastic, prevent the chain from falling off, particularly during aggressive riding or off-road conditions.

Manufacturers strongly advise using only prescribed replacement guide rails and chains, as incorrect parts can lead to saw malfunctions and potential hazards. Proper maintenance ensures optimal performance.

Industrial Chain Drives

In industrial settings, chain drives are favored for their compact construction and positive transmission capabilities, often surpassing belt drives. Chain guides are essential components, ensuring reliable power transfer over both short and long distances to multiple shafts.

These guides prevent chain derailment, minimizing downtime and maintaining operational efficiency. Utilizing manufacturer-recommended replacement parts is crucial for preventing malfunctions and ensuring long-term system reliability.

Benefits of Using Chain Guides

Chain guides deliver substantial advantages by actively preventing chain derailment, a common issue that interrupts operation and requires repair. They significantly reduce unwanted chain noise, creating a more pleasant and safer working environment.

Furthermore, consistent use extends both the chain’s lifespan and the life of related components, minimizing replacement costs and maximizing return on investment. Proper maintenance and correct replacement parts are key.

Preventing Chain Derailment

Chain derailment is a frequent problem, especially in demanding applications like 1x bicycle drivetrains and industrial machinery. Chain guides effectively address this by physically containing the chain, ensuring it remains properly positioned on the sprockets or gears.

This containment is vital, preventing costly interruptions and potential damage. Whether on trails, gravel, or roads, guides minimize dropped chains, enhancing reliability and performance.

Reducing Chain Noise

Excessive chain noise can indicate misalignment or improper tension, leading to wear and reduced efficiency. Chain guides contribute to quieter operation by maintaining consistent chain alignment and minimizing slack.

This is particularly important in applications where noise reduction is critical, such as certain industrial settings or for a more enjoyable riding experience. Properly installed guides dampen vibrations and prevent the chain from slapping against other components.

Extending Chain and Component Life

Chain guides significantly prolong the lifespan of both the chain and related drivetrain components. By preventing derailment and maintaining proper alignment, guides reduce stress and wear on the chain, sprockets, and other parts.

Consistent, correct chain positioning minimizes friction and premature failure, ultimately lowering maintenance costs and downtime. Always use manufacturer-prescribed replacement parts for optimal performance and longevity.

Chain Drive Mechanics & Efficiency

Chain drives excel due to their positive transmission characteristics, offering a distinct advantage over belt drives with their compact construction. They deliver high transmission efficiency, capable of transferring power effectively over both short and long distances to multiple shafts.

Furthermore, chain drives accommodate high speed ratios, making them ideal for diverse applications where precise and reliable power transfer is paramount.

Positive Transmission Advantages

Chain drives provide a “positive” transmission, meaning there’s no slippage – unlike belts. This characteristic ensures immediate power transfer and precise synchronization between the driving and driven components. This is particularly vital in applications demanding accurate timing and consistent performance.

The interlocking nature of the chain links guarantees a reliable connection, eliminating the potential for lost motion or efficiency reductions.

High Transmission Efficiency

Chain drives boast remarkably high transmission efficiency, often exceeding 98% under optimal conditions; This minimal energy loss stems from the positive engagement between the chain and sprockets, reducing wasted power as heat or friction.

Compared to other transmission methods, chains deliver more of the input power to the output, making them ideal for applications where maximizing efficiency is paramount.

Power Transmission Over Distance

Chain drives excel at transmitting power effectively, whether over short or substantial distances to multiple shafts. This capability makes them versatile for complex machinery and systems requiring synchronized movement across varied layouts.

Unlike belts, chains maintain consistent tension and positive engagement, preventing slippage and ensuring reliable power delivery even with extended spans between driving and driven components.

Silent Chain Technology

Silent chains represent an advancement in chain drive design, prioritizing quieter operation without sacrificing strength or efficiency. A key feature is the double-meshing design, where link plates boast identical side profiles and two meshing teeth.

This configuration, coupled with a flat back face on each link plate, minimizes the impact and noise typically associated with standard chain operation, making them ideal for sensitive applications.

Double-Meshing Silent Chains

Double-meshing silent chains are engineered for remarkably quiet power transmission, a significant improvement over conventional roller chains. These chains utilize specifically designed link plates featuring identical side profiles for smooth engagement.

Each plate incorporates two meshing teeth and a flat back face, effectively reducing the slapping and clicking sounds common in standard chains. This design enhances operational comfort and suitability for noise-sensitive environments.

Link Plate Design

The sophisticated link plate design is central to the functionality of silent chains, ensuring optimal performance and quiet operation. Each plate boasts two precisely engineered meshing teeth, crucial for smooth and consistent power transfer.

Furthermore, the inclusion of a flat back face minimizes friction and reduces the characteristic noise associated with traditional chain drives. This meticulous design contributes to enhanced durability and a quieter, more efficient system.

Chain Guide Maintenance and Replacement

Consistent maintenance and timely replacement of chain guides are paramount for optimal system performance and longevity. Manufacturers provide specific recommendations regarding inspection intervals and replacement schedules, which should be strictly followed.

Using incorrect replacement parts can severely compromise the system’s integrity, potentially causing damage to the saw or other connected components. Always prioritize manufacturer-prescribed guides and chains for safe and reliable operation.

Manufacturer Recommendations

Adhering to manufacturer recommendations is critical for chain guide maintenance and replacement. These guidelines detail specific inspection frequencies, wear limits, and appropriate replacement intervals tailored to each system’s design and operating conditions.

Always utilize the manufacturer’s prescribed guide rails and saw chains; deviations can lead to system failure and potential hazards. Following these recommendations ensures optimal performance, safety, and prolongs the lifespan of your chain drive system.

Importance of Correct Replacement Parts

Using incorrect replacement guide rails and saw chains poses significant risks to your chain drive system. Mismatched components can compromise chain alignment, increase friction, and accelerate wear on both the chain and surrounding components;

Incorrect parts may even cause catastrophic saw failures, highlighting the necessity of sourcing genuine, manufacturer-approved replacements. Prioritizing correct parts ensures compatibility, maintains system integrity, and safeguards against costly damage or downtime.

Chain Guide Technology & Innovation

Recent advancements focus on safe technology utilization, exemplified by the Trusted Tech Alliance – a collaboration between fifteen companies, including Microsoft and Ericsson. This alliance champions five principles for responsible tech deployment, regardless of origin.

Innovation extends to materials and designs, aiming for enhanced durability and performance. These efforts ensure chain guides remain effective in increasingly demanding applications, promoting reliability and longevity within various drive systems.

Trusted Tech Alliance & Safe Technology Use

Launched on Friday, the Trusted Tech Alliance, spearheaded by Microsoft and Ericsson, addresses the critical need for secure and ethical technology implementation. Built upon five core principles, the alliance promotes responsible innovation and safeguards against potential risks associated with emerging technologies.

This initiative ensures chain guide technology, and related systems, benefit from a framework prioritizing safety and trustworthiness, fostering confidence in their performance and reliability across diverse industrial and consumer applications.

Microsoft & AI Impact on Chain-Related Industries

Microsoft’s AI chief, Mustafa Suleyman, predicts AI will automate white-collar jobs within 12-18 months, impacting industries reliant on chain technology. This includes optimizing chain guide design, predictive maintenance scheduling, and streamlining supply chains for components like nylon plus fiber and Saigang engineering plastics.

AI-driven automation promises increased efficiency in chain drive manufacturing and quality control, potentially revolutionizing the production of bicycle, motorcycle, and industrial chain systems.

AI Automation of White-Collar Jobs

Mustafa Suleyman of Microsoft forecasts AI’s rapid advancement will automate numerous white-collar roles within a year to eighteen months. This impacts chain-related industries by automating tasks like materials sourcing (Nylon plus fiber, Saigang plastic), design optimization of chain guides, and predictive maintenance scheduling for chain drives.

AI can analyze vast datasets to improve chain guide performance and reduce downtime, potentially displacing roles focused on manual analysis and reporting.

Data Disclosure & Governance (EITI)

The Extractive Industries Transparency Initiative (EITI) provides a framework for companies to identify and assess corruption risks within supply chains, including those for chain guide materials like nylon and engineering plastics. Transparent data disclosure aids in verifying responsible sourcing and ethical manufacturing practices.

EITI supports governance by ensuring accountability in revenue streams related to the production and distribution of components used in chain drives and guides.

Supporting Corruption Assessment

EITI data disclosure directly supports corruption assessment within the chain guide manufacturing process, particularly concerning material sourcing and financial transactions. This transparency allows for scrutiny of potential irregularities in the supply of nylon plus fiber and Saigang engineering plastics.

By revealing beneficial ownership and contract details, EITI empowers stakeholders to identify and mitigate corruption risks, ensuring ethical production of these vital components.

Gaming & Quest Chains

Legendary Quest chains, available February 17th to March 17th, offer rewards for ranked play, mirroring the reliable performance expected from well-maintained chain guides in real-world applications.

Just as a robust chain guide prevents derailment, completing these quest stages unlocks valuable in-game assets, demanding precision and consistent effort. The quest structure parallels the interconnected links within a chain drive system.

Legendary Quest Chains & Rewards

Participate in the first part of this Legendary Quest chain from February 17th to March 3rd, followed by the next stage from March 3rd to 17th, to earn exclusive rewards.

Similar to how chain guides ensure smooth power transmission, completing these quests provides tangible benefits within the game; Consistent engagement, like proper chain maintenance, unlocks greater potential and sustained success.