craftsman 3/4 hp garage door opener manual

Craftsman 3/4 HP Garage Door Opener Manual: A Comprehensive Guide

This manual provides detailed instructions for installing, operating, and maintaining your Craftsman 3/4 HP garage door opener, ensuring safe and reliable performance․

It covers warranty details, troubleshooting, and programming features like the Timer-to-Close function and smart device connectivity for enhanced control․

Craftsman garage door openers have long been a trusted name in home improvement, renowned for their durability and innovative features․ This manual specifically addresses the 3/4 HP model, designed to provide robust lifting power for a variety of garage door types․

These openers are engineered for residential use, prioritizing safety and convenience․ The 3/4 HP motor delivers sufficient strength for most single and double-car garages, even those with heavier doors or challenging inclines․

This guide will walk you through every step, from initial preparation and installation to programming remote controls and maintaining optimal performance․ Understanding the features and safety protocols outlined herein is crucial for ensuring years of reliable operation․ Referencing smartgdo․craftsman․com can provide additional support and connectivity options․

Understanding the 3/4 HP Model

The Craftsman 3/4 HP garage door opener represents a balance of power and efficiency, suitable for most residential applications․ This model utilizes a robust motor capable of handling standard and heavier garage doors with ease․ It’s designed to offer reliable performance, minimizing strain and extending the lifespan of the opener itself․

Key components include the motor unit, drive belt or chain, door arm, safety reversing sensors, and control systems․ The 3/4 HP designation indicates the motor’s horsepower, directly correlating to its lifting capacity․

Features like the Timer-to-Close function and compatibility with the Craftsman Garage Door app enhance convenience and security․ Proper installation and maintenance, as detailed in this manual, are vital for maximizing the benefits of this powerful opener․

Safety Precautions

Prioritizing safety is paramount when installing and operating your Craftsman 3/4 HP garage door opener․ Disconnect power before any maintenance or installation․ Never allow children to play near the door or operate the controls․ Regularly test the safety reversing system to ensure it functions correctly, preventing potential entrapment․

Always keep the garage door balanced; an unbalanced door can cause serious injury․ Do not attempt to repair or modify the opener beyond the scope of this manual․

Be mindful of the emergency release mechanism and understand how to use it safely․ Proper sensor alignment is crucial for preventing accidental closures․ Following these precautions will contribute to a safe operating environment․

General Safety Warnings

Serious injury or death may result from improper installation or use of this garage door opener․ Disconnect electrical power at the circuit breaker before installing or servicing․ Never operate the opener while anyone is underneath the door․ Regularly inspect the door, springs, cables, and hardware for signs of wear or damage;

Do not allow anyone, especially children, to play in the area of the garage door․ Keep the area clear of obstructions․ The safety reversing system must be tested monthly․

Failure to follow these warnings could lead to severe consequences․ Always refer to the complete manual for detailed safety instructions and operational guidelines․

Specific Safety Instructions for Installation

Ensure the garage door is balanced before installation; an unbalanced door can cause serious injury․ Use proper lifting techniques and seek assistance if the opener unit is heavy․ Securely mount the opener unit to avoid vibration and potential detachment․

Carefully position the emergency release rope and handle in a readily accessible location, but out of reach of children․ Double-check all wiring connections to prevent electrical hazards․

Properly align safety reversing sensors to ensure they function correctly․ Test the system thoroughly after installation, and regularly thereafter, to confirm safe operation․

Emergency Release Procedures

In case of power failure or malfunction, locate the emergency release mechanism – typically a red handle attached to the door arm․ Pull the handle down and away from the opener to disengage the door․

Exercise caution, as the door may fall rapidly․ Use a clear path and keep hands and feet away from the door’s path․ Once disengaged, the door can be operated manually․

To re-engage, pull the handle back up and towards the opener until it clicks into place․ Test the opener’s operation with the safety reversing sensors before normal use․ Never attempt to repair the opener while it’s connected to power․

Installation Guide

Proper installation is crucial for safe operation․ This section details mounting, door arm attachment, sensor placement, and electrical connections for your Craftsman opener․

Preparing for Installation

Before beginning, carefully unpack and inspect all components to ensure nothing is missing or damaged․ Verify you have the opener unit, rail sections, door arm assembly, safety sensors, hardware kit, and remote controls․

Clear the garage area, removing any obstructions above the door and along the rail’s path․ Disconnect the existing garage door from the manual release mechanism․ Ensure the door is balanced; a properly balanced door should stay stationary midway when opened or closed manually․

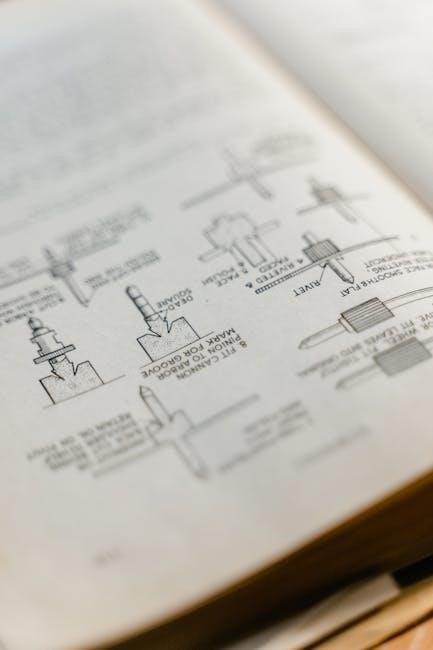

Gather necessary tools: adjustable wrench, socket set, screwdriver set, drill, ladder, and wire strippers․ Review the wiring diagram to understand electrical connections․ Confirm the electrical supply matches the opener’s voltage requirements, and always prioritize safety by turning off power at the breaker․

Mounting the Opener Unit

Position the opener unit on the ceiling, ensuring adequate clearance for the door’s travel and rail assembly․ Utilize the provided mounting brackets, securely attaching them to ceiling joists using appropriate hardware – lag screws are typically recommended for a stable hold․

Confirm the opener is centered above the door and aligned with the rail’s intended path․ Double-check bracket stability before proceeding․ Assemble the rail sections, connecting them securely according to the manual’s illustrations․

Attach the assembled rail to the opener unit, ensuring a snug fit and proper alignment․ Support the rail during attachment to prevent strain on the mounting brackets; Verify the entire assembly is level and firmly secured before moving to the next installation step․

Attaching the Door Arm

Connect the door arm to the garage door, utilizing the pre-drilled holes or creating new ones as needed, ensuring a secure and stable connection․ The arm’s position dictates the door’s lift arc, so precise placement is crucial for smooth operation․

Attach the other end of the door arm to the trolley on the opener unit, again verifying a firm connection․ Adjust the arm’s length to achieve the correct door travel – typically, a few inches of travel beyond the fully open and closed positions is recommended․

Ensure the arm moves freely without binding and that the door operates smoothly through its entire range of motion․ Proper arm attachment is vital for efficient and safe garage door operation․

Sectional Door Attachment

For sectional doors, the door arm connects to a reinforced strut on the door itself, typically the center panel․ Ensure this strut is securely mounted to the door sections to prevent stress or damage during operation․ Proper alignment is critical; the arm should form a relatively straight line with the door’s vertical track․

Adjust the arm’s length to achieve the desired door travel, allowing for a few inches of movement beyond the fully open and closed positions․ This ensures complete opening and closing without strain on the opener․

Verify the door panels move evenly and smoothly throughout the entire cycle․ Incorrect attachment can lead to uneven operation or potential safety hazards․

One-Piece Door Attachment

Attaching to a one-piece door requires a specialized mounting bracket, often included with the opener kit․ This bracket secures to the door itself, providing a stable connection point for the door arm․ Reinforce the door frame where the bracket is mounted, as one-piece doors are typically heavier and exert more force․

Carefully position the bracket to ensure the door arm pulls straight back when activated, avoiding any sideways stress․ Adjust the arm length to allow for full door travel, ensuring it doesn’t bind or hit obstructions․

One-piece doors may require additional support or bracing to function reliably with an opener; consult a professional if unsure․

Installing the Safety Reversing Sensors

Safety reversing sensors are crucial for preventing injuries; they detect obstructions in the door’s path․ Mount the sensors approximately six inches above the floor on either side of the garage door opening, ensuring they face each other directly․

Use the included brackets to secure them firmly, avoiding any wobble or misalignment․ Proper alignment is vital – the sensors must be level and pointed at each other for reliable operation․

Wiring the sensors involves connecting them to the opener unit using the provided low-voltage wires, following the wiring diagram carefully․ Test the system after installation to confirm functionality․

Sensor Placement and Alignment

Precise sensor placement is paramount for safety․ Position the safety reversing sensors six inches above the floor, on both sides of the garage door opening․ Ensure they are directly across from each other, creating an invisible beam across the doorway․

Alignment is critical; the sensors must be level and accurately pointed․ Misalignment can cause false triggers or prevent the safety system from functioning correctly․ Use a level to verify horizontal alignment and adjust as needed․

Avoid obstructions within the sensor beam’s path, and regularly inspect for dust or debris that could interfere with the signal․

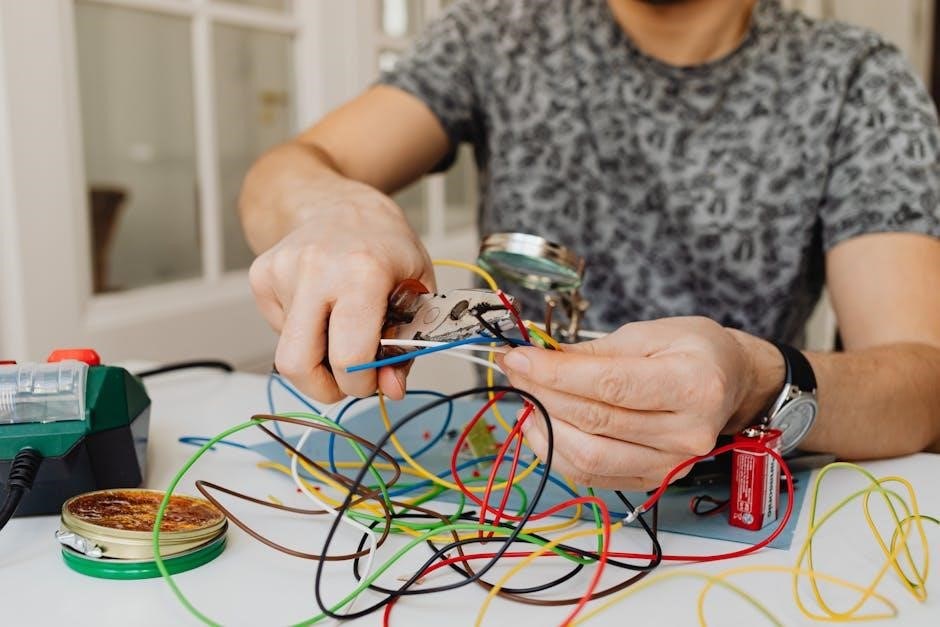

Wiring the Safety Sensors

Connect the safety sensor wires to the designated terminals on the garage door opener unit․ Typically, these are labeled “Sensor” or “Safety Sensors․” Ensure the wiring is secure and follows the color-coding provided in the opener’s wiring diagram․

Usually, a two-conductor wire connects each sensor to the opener․ Double-check that the connections are firm to prevent intermittent signals․ Incorrect wiring can disable the safety features, compromising safety․

Before proceeding, disconnect power to the opener․ After wiring, carefully inspect all connections and ensure no bare wires are exposed․ Proper wiring is essential for the safety reversing system to operate effectively․

Testing the Safety Reversing System

After wiring the safety sensors, thoroughly test the system to confirm proper functionality․ With the door closed, manually obstruct the infrared beam path between the sensors․ The garage door should immediately stop and reverse to the open position․

Repeat this test several times, varying the obstruction point․ If the door fails to reverse, re-check the wiring connections, sensor alignment, and ensure nothing is interfering with the beam․

A functioning safety system is crucial for preventing injuries․ Never bypass or disable this feature․ Consistent testing, as part of regular maintenance, guarantees continued safe operation of your Craftsman garage door opener․

Electrical Requirements & Connections

Proper voltage and circuit capacity are essential for safe operation․ Refer to the wiring diagram for correct connections and always follow grounding instructions carefully․

Voltage and Circuit Requirements

Ensuring correct electrical supply is paramount for the safe and efficient operation of your Craftsman 3/4 HP garage door opener․ This opener typically requires a 120-volt, 60 Hz electrical supply․ A dedicated 15-amp circuit is strongly recommended to prevent overloading and potential issues with other household appliances․

Avoid using extension cords, as they can cause voltage drop and potentially damage the opener’s motor․ The electrical outlet should be readily accessible but protected from the elements․ Before commencing any electrical work, always disconnect power at the circuit breaker to avoid the risk of electric shock․ Consult a qualified electrician if you are unsure about any aspect of the electrical installation․

Incorrect voltage or an inadequate circuit can lead to malfunction, reduced lifespan, or even a fire hazard․ Prioritize safety and adhere to local electrical codes․

Wiring Diagram Explanation

The wiring diagram, typically found inside the opener unit’s housing, is crucial for correct installation and troubleshooting․ It illustrates the connections between the power source, the opener motor, safety sensors, wall control, and remote receiver․

Pay close attention to wire colors: black for hot/live, white for neutral, and green or bare copper for grounding․ The diagram details how to connect the safety reversing sensors, ensuring the door reverses upon obstruction․ The wall control wiring shows connections for the push buttons․

Incorrect wiring can damage the opener or create a safety hazard․ If unsure, consult a qualified electrician․ Always double-check connections against the diagram before restoring power․

Grounding Instructions

Proper grounding is essential for safety, reducing the risk of electric shock and preventing damage to the opener’s electrical components․ The opener must be connected to a grounded electrical outlet, conforming to local electrical codes․

The opener’s power cord includes a grounding wire – typically green or bare copper․ This wire must be securely connected to the grounding terminal within the electrical outlet box․ Never disconnect or bypass the grounding wire․

If an extension cord is necessary, use a heavy-duty, three-wire grounded cord․ Ensure the outlet is properly grounded․ If you are unsure about grounding procedures, consult a qualified electrician for assistance․

Operation and Programming

Successfully operate and customize your Craftsman opener by programming remote controls, wall panels, and the convenient Timer-to-Close feature for automated security․

Remote Control Programming

To program a new remote control, locate the “Learn” button on the garage door opener motor unit – it’s typically yellow or orange․ Press and release this button․ Within 30 seconds, press and hold the button on your remote control until the garage door opener light flashes, indicating successful programming․

If you have multiple remotes, repeat this process for each one․ If the programming fails, ensure the remote has fresh batteries and try again․ Some models may require clearing existing remote codes before adding new ones; consult the full manual for specific instructions․ The Craftsman Garage Door app also offers remote control functionality, providing convenient smartphone access and control․

Remember to test the remote after programming to confirm proper operation․

Wall Control Programming

Programming the wall control panel mirrors the remote control process․ Locate the “Learn” button on the garage door opener motor unit and press it briefly․ Within the 30-second window, press and hold the button on the wall control panel until the opener’s light flashes, confirming successful synchronization․

The wall control provides a convenient, fixed location for operating your garage door․ If the wall control isn’t responding, check its wiring connections and ensure it’s receiving power․ Clearing existing codes might be necessary before programming a new wall control, as detailed in the comprehensive owner’s manual․

Always test the wall control after programming to verify its functionality and ensure seamless operation alongside your remote controls․

Timer-to-Close Feature Setup

The Timer-to-Close (TTC) feature automatically closes your garage door after a pre-set time, enhancing security and convenience․ To activate, locate the TTC button on your wall control panel․ Press and hold it until the indicator light illuminates, signifying the feature is enabled․

The default TTC duration is typically 10 minutes, but this can be adjusted via the opener’s programming sequence․ Consult the manual for specific instructions on modifying the timer duration to suit your needs․ Ensure the garage is clear of obstructions before activating TTC․

Remember, TTC can be overridden by pressing the wall control or remote before the timer expires․ The Craftsman Garage Door app also offers TTC control․

Maintenance and Troubleshooting

Regular maintenance ensures optimal performance and longevity․ This section details schedules, common issue resolutions, and instructions for replacing components like the drive belt․

Regular Maintenance Schedule

To maintain peak performance and ensure the longevity of your Craftsman 3/4 HP garage door opener, a consistent maintenance schedule is crucial․ Monthly, visually inspect the entire system, checking for loose bolts, frayed cables, and any signs of wear or damage․ Lubricate all moving parts – rollers, hinges, and the drive belt – with a silicone-based lubricant, avoiding oil-based products which can attract dust․

Every six months, thoroughly test the safety reversing system to confirm it’s functioning correctly․ Annually, inspect the drive belt for cracks or wear, replacing it if necessary․ Clean the photo-eye sensors with a soft cloth to ensure unobstructed operation․ A proactive approach to maintenance will minimize potential issues and extend the life of your opener, saving you time and money in the long run․

Troubleshooting Common Issues

Encountering problems with your Craftsman 3/4 HP garage door opener? A common issue is the door reversing unexpectedly – check the safety sensors for obstructions or misalignment․ If the opener doesn’t respond, verify the power supply and remote control batteries․ A clicking sound but no movement suggests a potential issue with the drive gear or belt․

For doors that open partially, examine the travel limits and adjust as needed․ If the safety reversing system is overly sensitive, slightly adjust the sensor alignment․ Always disconnect power before performing any repairs․ Refer to the detailed wiring diagram for electrical troubleshooting․ If issues persist, consult a qualified technician for assistance․

Replacing the Drive Belt

A worn or damaged drive belt can cause operational issues with your Craftsman 3/4 HP opener․ Begin by disconnecting the power supply to the unit․ Carefully remove the opener’s cover to access the belt and pulleys․ Note the belt’s routing before removal for correct reinstallation․

Loosen the motor mount bolts to create slack, then remove the old belt․ Install the new belt, ensuring it’s properly seated on all pulleys․ Retighten the motor mount and verify the belt tension․ Reconnect the power and test the opener’s operation․ A properly replaced belt restores smooth, quiet operation․ Always use a replacement belt specified for your model․

Warranty Information

Craftsman offers a 90-day full warranty covering defects in materials and workmanship․ A limited warranty extends from 91 days to one year, covering parts only․

90-Day Full Warranty Details

For the initial 90 days following the date of purchase, Sears provides a comprehensive full warranty on your Craftsman 3/4 HP garage door opener․ This warranty meticulously covers any demonstrable defect in either the materials utilized during construction or the quality of the workmanship itself․

During this period, Sears will, at no cost to you, undertake the necessary repairs to rectify any such defects․ This includes both the cost of parts and the labor required to complete the repair․ Should a repair be deemed impossible, Sears reserves the right to replace the entire garage door opener unit with a comparable model․ To initiate a warranty claim within this 90-day window, proof of purchase is essential․

Limited Warranty (91 Days ౼ 1 Year)

Extending beyond the initial 90-day full warranty, a limited warranty remains in effect from the 91st day up to one full year from the original purchase date․ This limited warranty specifically addresses defective parts within your Craftsman 3/4 HP garage door opener․

During this extended period, Sears will furnish replacement parts, free of charge, for any component found to be defective․ However, it’s crucial to understand that this limited warranty does not cover the cost of labor associated with installing these replacement parts․ The homeowner is responsible for all labor charges incurred during the repair process․ Proof of purchase remains a requirement for all warranty claims․

Motor Specific Warranty Information

Craftsman extends a dedicated limited warranty specifically for the 1/2 HP motors utilized in their garage door openers, including compatible 3/4 HP models․ This warranty provides additional coverage beyond the standard limited warranty, recognizing the motor as a critical component․

While the general limited warranty covers parts, this motor-specific provision may offer extended protection or different terms related to motor failure․ Details regarding the duration and specific conditions of this motor warranty are outlined separately in supplemental documentation․ Always refer to the accompanying motor warranty card or contact Sears customer service for precise information regarding your motor’s coverage․